InnoTech Alberta is well-versed in the most up-to-date non-destructive testing (NDT) techniques, such as laser (optical) scanning and ultrasonic testing (UT) and inspection. These methods allow us to conduct non-invasive and cost-effective inspection and monitoring solutions and procedures for industrial assets.

Comprehensive NDT testing can significantly reduce the probability of asset failure and increase service life. InnoTech Alberta works with industrial clients to develop improved inspection and monitoring solutions to support our clients’ preventative maintenance programs.

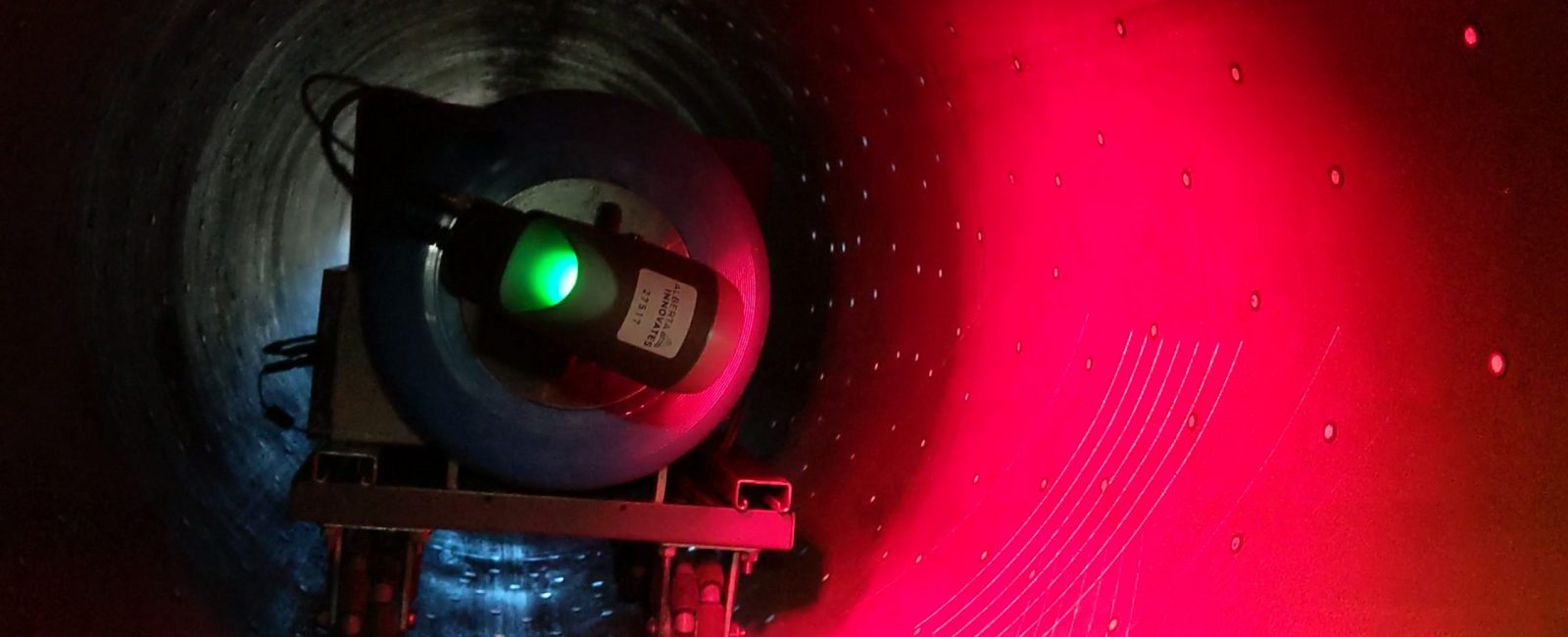

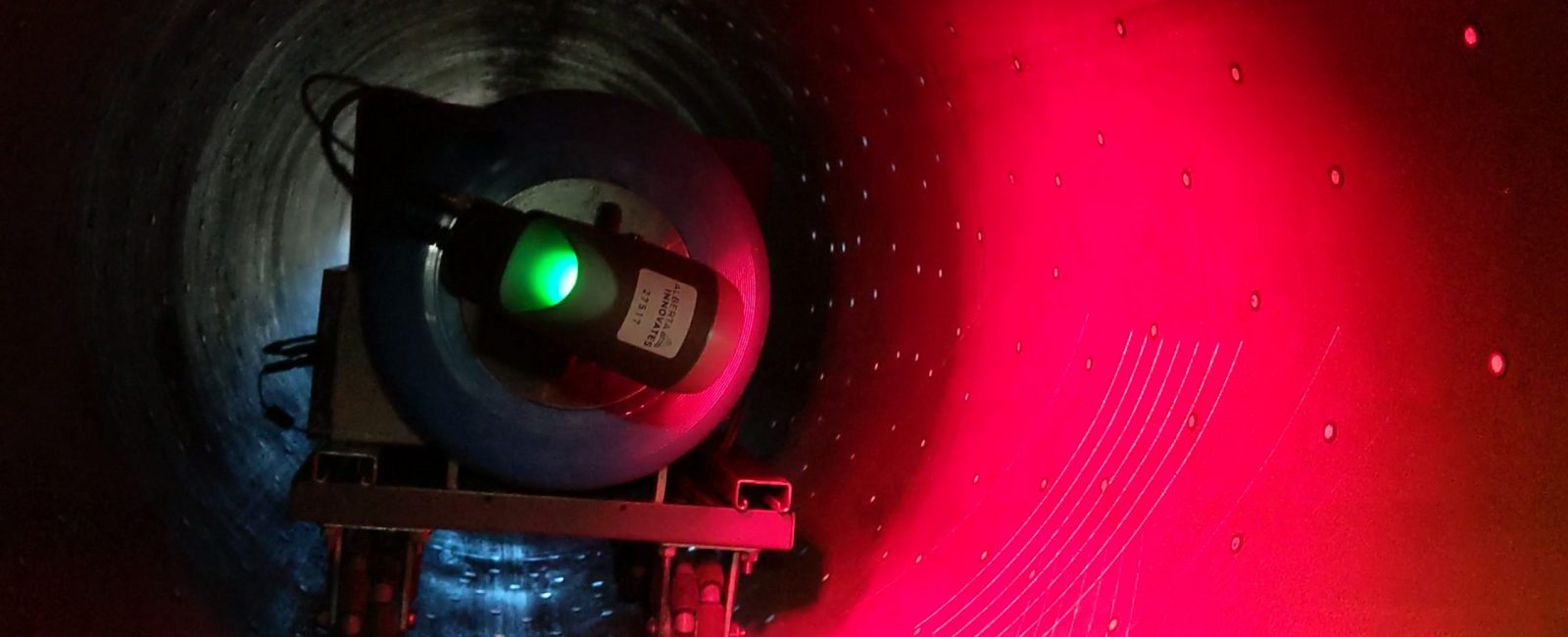

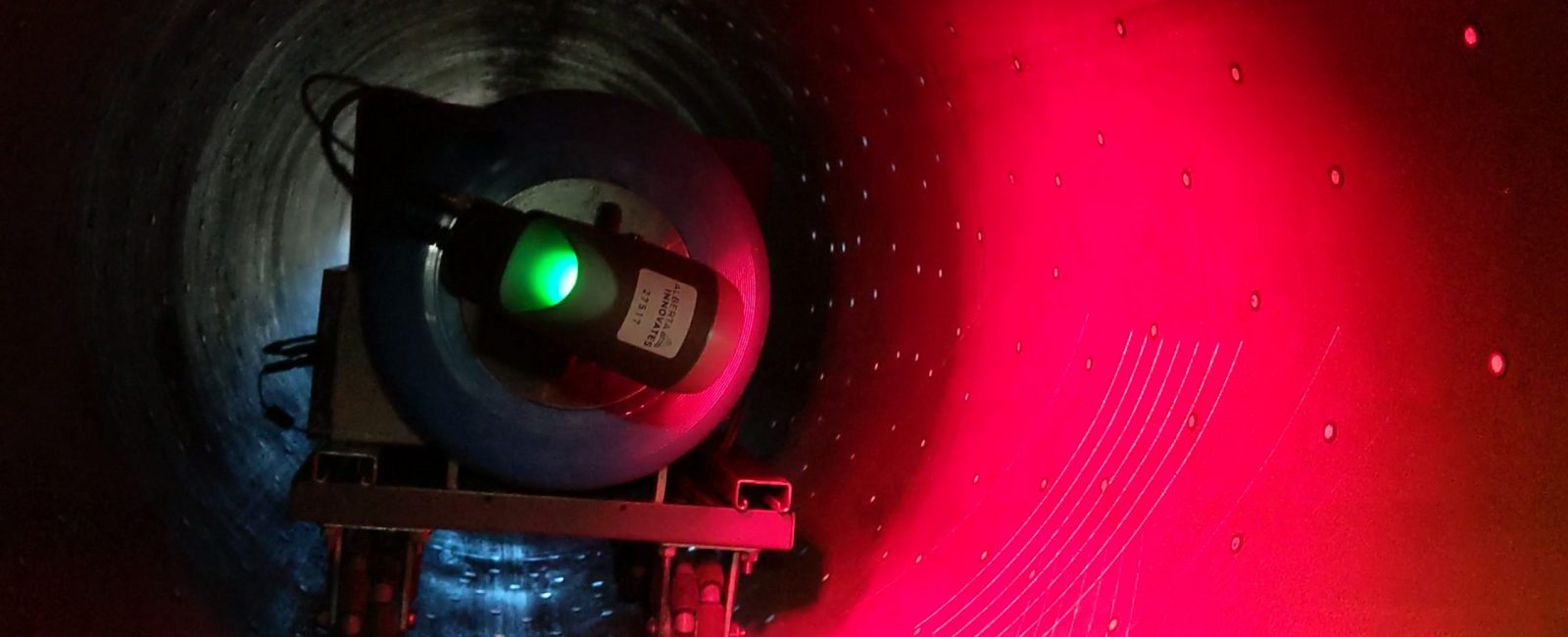

InnoTech Alberta uses a range of commercial and custom laser optical scanning tools for measurement of wear, corrosion, and dimensional changes in process equipment (for example: pumps and piping components) and structures. We use the following laser scanning tools in our testing and research projects:

InnoTech Alberta staff works with vendors, service providers, and end users to develop and de-risk custom inspection solutions and inspection procedures for challenging asset monitoring applications where existing commercial solutions either do not exist or are unsuitable. Examples of our specific expertise include: