Mining Equipment

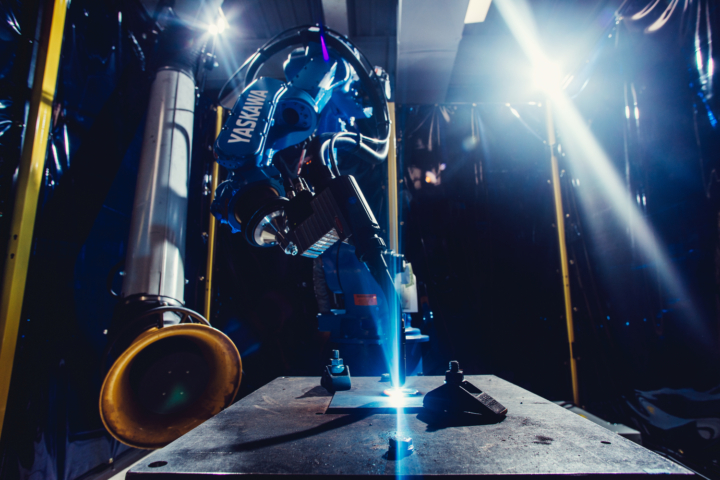

Oilsands surface mining equipment operates in extremely harsh conditions where rapid wear and high equipment failure rates result in high maintenance costs, unexpected failures, and expensive process bottlenecks.

Operators have identified several focus areas where the impacts are most significant. These areas include electric rope shovel ground engaging tools (GETs), dozer and grader GETs, dozer undercarriages, rope shovel cables, and haul truck tires. To prioritize efforts, this portfolio will focus on electric rope shovel ground engaging tools (GETs) and haul truck tires. These components are singled out due to their high impact on the value chain, the high rate of wear and high cost of replacements. Improvements to the wear and reliability will reduce maintenance costs and, in some cases, prevent the need for an increase in equipment fleet size to cover downtime.

Portfolio Manager: Gary Fisher