InnoTech Alberta works with clients who work with processes that require high temperatures or high pressure in their processes. We have dedicated facilities to engage in research and testing under these conditions.

Our steam flow, emulsion testing, micro model capabilities, scaled model sandpack systems, fat tube – coreflood systems, and chemical reactors all help us conduct our work and provide effective and innovative results for our clients.

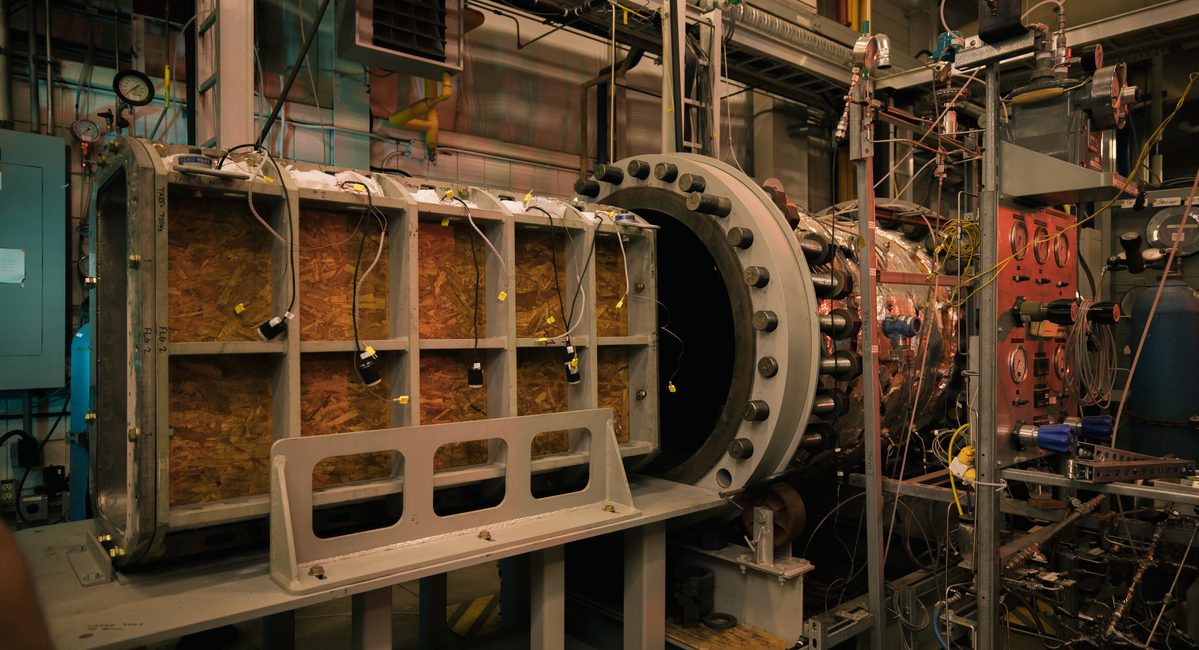

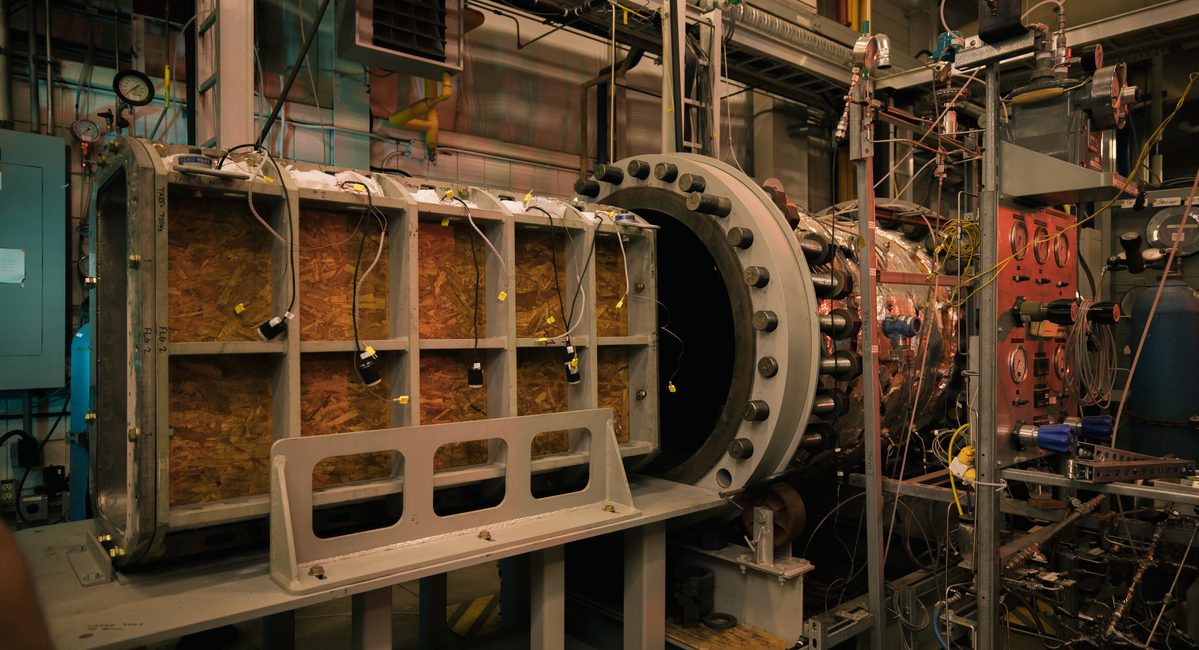

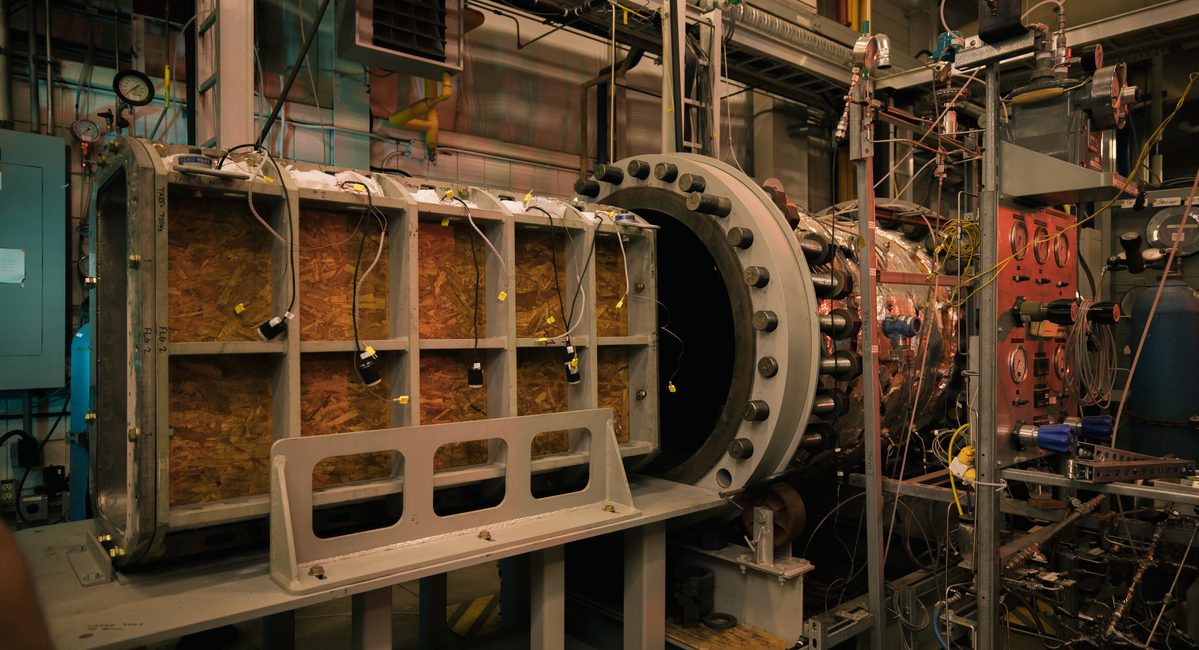

The HPHT steam flow facility is a multi-purpose setup located in a high-head engineering lab and capable of dry steam flow rates as high as 200 kg/h, at 4 MPa, and temperatures up to 250°C.

The facility includes a unique hot water injection system that allows control of the steam quality from 0 to 100%. It is typically used to evaluate the performance of various downhole flow control devices, multiphase meters, and elastomers under stable and flashing steam conditions.

The facility consists of two multi-purpose flow loops that are typically used to test components in thermal heavy oil/bitumen production and processing operations. The facility is capable of circulating fluids with water cuts ranging from 50 to 100%, flow rates up to 10 kg/min, and temperatures up to 300°C.

We can also accommodate testing and procedures requiring high-shear mixing of oil and water within the facility. This allows for custom fluid blends to be emulsified during circulation experiments. Previous projects include the experimental determination thermal production fluid properties and fouling mitigation in heat exchangers.

This facility may be used to generate detailed information such as oil production performance, development of oil depletion zones, temperature profiles, and solvent fronts for oil recovery processes.

These processes include SAGD, ES-SAGD and steam flooding characteristics in a scale comparable to the field scale, to quantify the key (such as solvent mixing, solvent mobilizing oil and gravity segregation) mechanisms in the oil recovery process.

The group of experimental setups includes:

Micro models are essentially laboratories on a glass chip that can allow the visualization of miscible and immiscible displacement flow in a porous medium under extreme pressure (up to 20,000 psi) and temperature (>300°C). This system is often used to observe the displacement of oil by water or steam to gain insight into the oil recovery mechanisms.

The latest feature includes a novel motorized dual camera system that allows the operator to identify an area of interest on the global-view camera and direct the high-resolution camera to the target with a click of the mouse. This new feature supports image capturing of dynamic processes occurring in the model. Collected images and videos can visualize flow mechanisms of a given process. PVT behaviour, dynamic asphaltenes precipitation and IFT measurements can be additional features added to the apparatus. InnoTech Alberta can operate or manufacture this apparatus to client specifications.

The apparatus is a 1-in diameter by 18 m long coreflood system that can provide flow displacements in a porous medium over a relatively large distance. The apparatus has been used to study the long-distance propagation of foam under steam temperatures and pressures.

The facility has a maximum allowable working pressure 3600 psig and has been successfully used at experimental temperatures as high as 230°C. Multiple ports and sensors allow for differential pressure measurement across 11 sections along its length. The system can also accommodate a large variety of pack permeabilities and test flow rates.

Various chemical reactors (autoclaves) are available for general experimental work at high temperatures and pressures. Our multi-purpose inventory can accommodate volumes from 300 mL to 6 L, pressures to 3000 psig, and temperatures to 350°C.

Depending on the unit available, vessel material is either 316SS or Hastelloy C276 and may have high-shear, stirring capabilities. A vast of inventory of auxiliary HPHT equipment (e.g. pumps, ovens, instrumentation, data acquisition) are also available to create any custom and unique experimental apparatus required. As past examples, these reactors have been used to study: