We can design, engineer, and provide research and development direction in metallic and composite manufacturing. This service is especially advantageous for oil sands, mining and pipeline applications.

We can design, engineer, and provide research and development direction in metallic and composite manufacturing. This service is especially advantageous for oil sands, mining and pipeline applications.

From metallographic analysis, wear and stress resistance, corrosion resistance, anti-fouling technology, to the analysis of the integrity of protective coatings; InnoTech can provide valuable consulting expertise in material selection and performance.

Using computer software (such as CAD) and object scanners we can develop designs and create prototypes from metals, polymers, and composite materials. For polymer builds we generally use smaller desktop 3D printers and our Wire Arc Additive Manufacturing facility (WAAM) for large-scale metallic and composite builds.

Additive manufacturing / 3D printing reduces the risk in process development and equipment selection. It allows for the proper selection of consumable materials and the evaluation of parts created using 3D printing technology; allowing more flexibility in manufacturing, more consistent quality, increased sustainability, and reduced costs when compared to traditional methods.

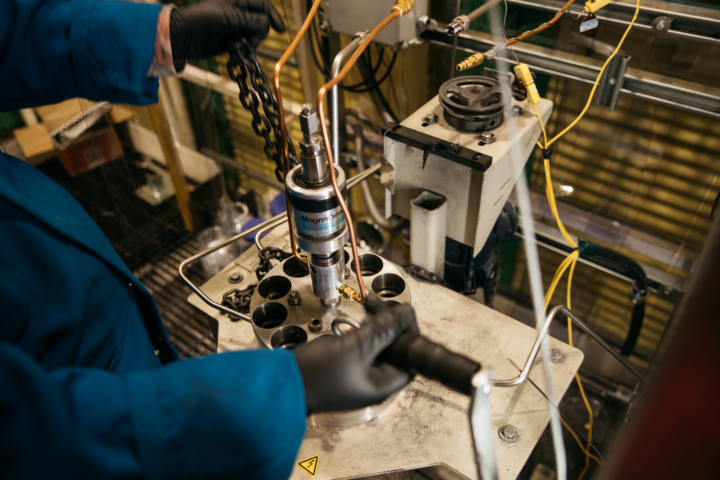

Enhance welding quality and productivity through advancement and de-risking of welding and inspection

technologies, Support development, adaptation, and deployment of new welding procedures.