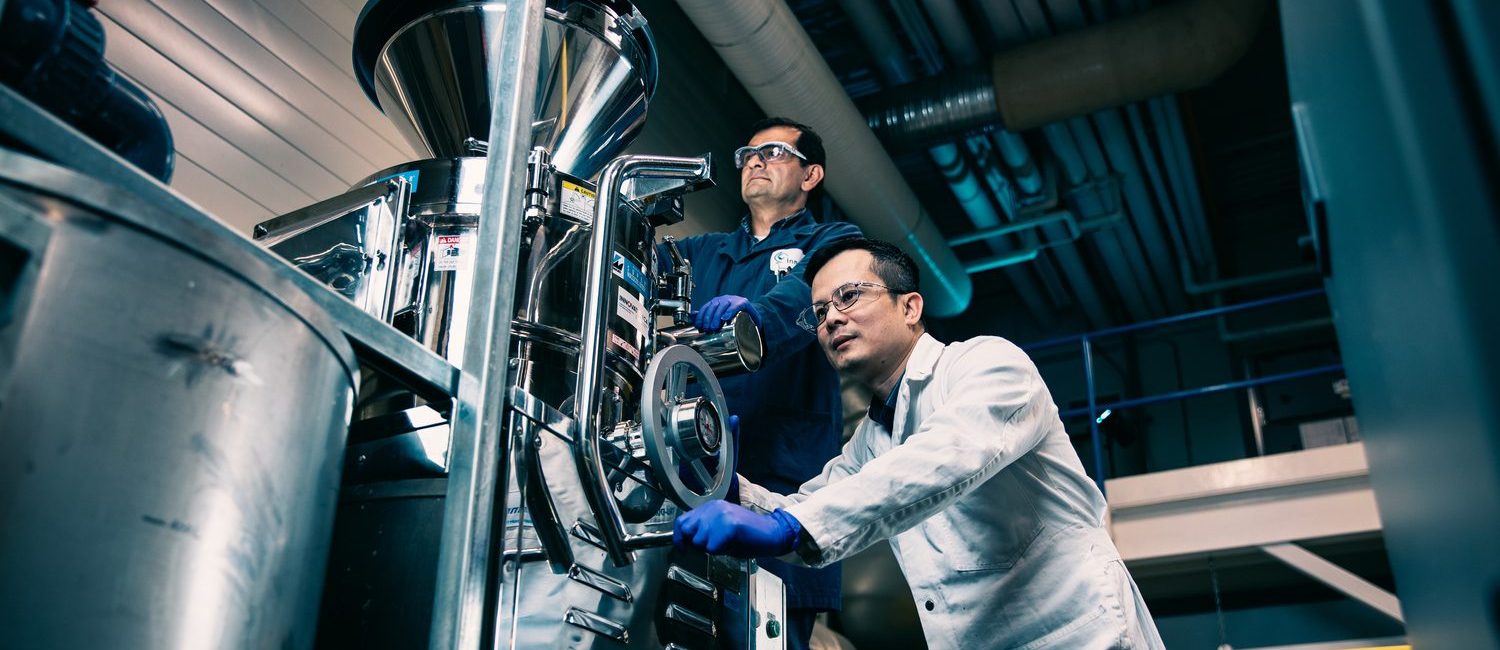

We routinely formulate the processes and develop novel, eco-friendly bioproducts using renewable, sustainable materials including biopolymers, biofibres, bioresins, biocomposites, bio-based coatings, bio-based nanocomposites, natural fibres, nanocellulose, lignin, bio-based corrosion inhibitor/protection, adhesives, rubber, carbon fibres, self-healing/shape memory/smart materials, plastic film, packaging, green release agents, fire retardants, and recycled materials. These bio-materials form part of the circular economy for a variety of applications and industries with more sustainable products and packaging. Our work is complemented with a range of equipment and services including:

- Equipment for polymer/biopolymer/bioresins, bioplastics/bio-based polymers & resins, composite/biocomposite, nanocomposite/ bio-based nanocomposites, recycled materials, compostable/biodegradable processes

- Extruders/compression molding/spray-p/resins transfer molding

- Blowing film/Additive manufacturing (3D printing) facility

- Single screw extrusion, twin-screw extrusion, blending/Brabender, extruding, pelletizing, masterbatch production

- Electrospinning, spinneret, melt-spinning, extruding

- Compression molding for up to 4’ x 8’ size biomaterial

- Spray-up, resin transfer molding

- Microfluidization and homogenization from micro to nanometers

- Formulation, compounding

- Additive manufacturing, 3D printing filament

- Reactors and blenders

- Fiber, biomass process, treatment, modification, conversion

- Thermal (TGA, DMA), mechanical (tensile, flexural, tear), physical (contact angle, rheology), chemical testing instruments

We also offer treatment, and modification of various biomaterials and the evaluation/analysis of the physical, chemical, thermal, and mechanical properties of these materials.