Industry 4.0 is the next step in a digital transformation influencing how products and parts are designed, fabricated, operated and serviced – all to help Alberta companies remain competitive in the face of globalization.

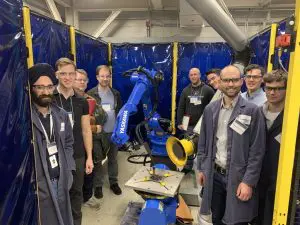

InnoTech Alberta continues to be a leader in this trend through its Alberta Manufacturing and Innovation (AMFI) program. Industry stakeholders recently gathered for an AMFI workshop to learn the benefits of digital manufacturing technologies through a series of presentations and equipment demonstrations.

Gary Fisher, Principal Researcher at InnoTech Alberta, says the program has a proven record of introducing commercial technologies to the manufacturing sector in Alberta.

“We have new tools such as the Industrial Internet of Things (IIOT), additive and smart manufacturing, new welding and joining technologies and the like, which will greatly benefit industry if we can adapt to improve efficiency and quality of things made in the province.

Workshop attendee Sean Lepine, of Enbridge, participated in a demonstration of a new digital welding process using data capture and visualization. He sees the value of this technology to better manage the full life cycle of a project from the first weld to the delivery of the final documentation to clients.

Workshop attendee Sean Lepine, of Enbridge, participated in a demonstration of a new digital welding process using data capture and visualization. He sees the value of this technology to better manage the full life cycle of a project from the first weld to the delivery of the final documentation to clients.

“Using data capture, this tool can identify an error as it’s happening or a deviation from your prescribed process as it’s happening. That allows you to mitigate a problem before it’s ever shipped to a client which saves down time, redos and, of course, money.”

The demonstration highlights how digital manufacturing technologies can be used to improve product design, production efficiency and equipment servicing.

“Part of our group’s push forward is looking at how we can actually take that data we collect during construction and utilize it on the asset management integrity side of our business,” says Lepine.

Tom Petruch, of the company Oerlikon Metco, is a repeat workshop attendee. He believes that while the digital revolution in manufacturing is already here, smaller companies remain slow to adopt. Part of the issue is cost, especially when the majority of manufacturers in Alberta are serving the slumping energy industry. However, he sees promise in adoption of additive manufacturing technologies, otherwise known as 3D printing using metal.

“The niche seems to be for the manufacture of complex pieces that would typically see two or three different parts being welded together. Now, 3D printing might be an option. There’s also a lot of options available for designing parts with different types of structural integrity that weren’t previously available using traditional manufacturing methods,” Petruch says.

Fisher believes the best way to remain at the head of the manufacturing curve is through information-sharing and the adoption of new processes and technologies.

“While the majority of our clients are energy-focused, we’d love to expand this program to include other industries like pulp and paper or paper or agriculture. The challenge is those are proportionately smaller markets than energy, so our next steps involve looking at ways we can invite the participation of new industries into the AMFI program.”