Built for industry

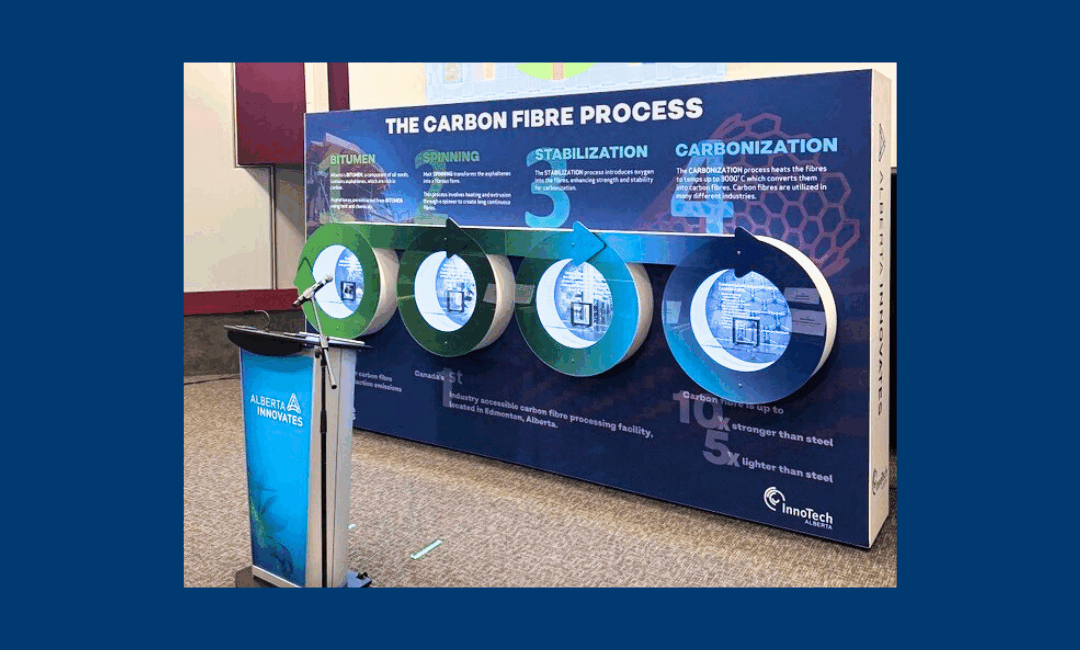

Traditional carbon fibre is made from petroleum-derived feedstock called PAN (polyacrylonitrile). Used in everything from aircraft and electric vehicles to wind turbines and medical equipment, carbon fibre has a role to fill in nearly every industry, but the cost of production has long held back widespread adoption. Producing carbon fibre from Alberta bitumen changes that equation by creating the potential to cut emissions by roughly half compared to traditional feedstock while reducing cost and unlocking entirely new applications.

This new processing facility, made possible by $10 million from Prairies Economic Development Canada and more than $1 million in upgrades from Infrastructure Alberta, offers something Canada has never had: a fully integrated carbon fibre testbed, open to industry, that spans feedstock preparation through to final fibre production. Its capabilities range from small-batch runs to continuous pilot-scale processing lines, allowing innovators to test, scale and validate their technologies at pre-commercial volumes.

“Carbon fibre isn’t just a material, it’s a catalyst,” says Alberta Innovates CEO Mike Mahon. “It’s where science meets sustainability, and where Alberta’s ingenuity takes flight.”

Why It matters for Alberta

Alberta’s energy sector remains a cornerstone of the provincial economy, but global competitiveness depends on innovation, diversification, and the ability to convert resources into higher-value products. Instead of using bitumen primarily in the combustion cycle, Alberta Innovates has advanced research that convert it into products such as carbon fibre, asphalt binders and energy carbons. The economic potential is significant. One barrel of bitumen worth roughly $50 can reach an estimated value of more than $233 when used in high-value products.

This is a benefit, not only for industry, but for the province as a whole — from diversifying Alberta’s economy to attracting investment and growing a new supply chain in advanced materials.

From research to real-world impact

One of the biggest barriers to the commercialization of carbon fibre is the gap between lab-scale research and market-ready production. This facility closes that gap.

The first users of the Carbon Fibre Processing Facility are the finalists from the Alberta Innovates Carbon Fibre Grand Challenge, a $20 million competition aimed at accelerating technologies that produce carbon fibre from bitumen-derived feedstocks. For companies like Fibernx — a British Columbia-based firm relocating to Alberta — the ability to validate processes at pilot scale is game-changing.

“This facility serves as the vital link between research and manufacturing,” says Fibernx President & COO Yasmine Abdin. “It allows us to validate our processes and prepare for real-world production. It’s the difference between an idea and a product.”

With continuous processing lines, filament spinners, feedstock reactors and extensive in-house expertise, the InnoTech Alberta facility gives innovators the flexibility to rapidly iterate, prototype and shorten their path to market. It also gives researchers and companies direct access to infrastructure that previously required international partners.

Building a new made-in-Alberta industry

The opening of the Carbon Fibre Processing Facility represents more than a technological milestone — it signals the emergence of a new advanced materials industry in Alberta.

As the Honourable Eleanor Olszewski, Minister responsible for PrairiesCan, noted at the announcement, investing in this transformation “will turn Alberta’s vast bitumen reserves into world-class carbon fibre, opening new markets and creating new opportunities for our province and the Prairie economy.”

A future built on innovation

Alberta Innovates continues to help chart Alberta’s energy future by supporting commercialization, turning research into solutions that companies can use, that investors can scale and that markets can adopt. The Carbon Fibre Processing Facility is a cornerstone of that work.

By reimagining what Alberta’s resources can become, the province is building an economy where energy innovation, advanced manufacturing and sustainability move forward together.

This is Alberta’s next chapter — made in Alberta, built for the world.

Carbon fibre facility processing line

|

|

|

Contacts

| Neil Yaremchuk Phone # 780-450-4628 Email neil.yaremchuk@innotechalberta.ca |

Jose Alvarez Phone # 780-450-5395 Email jose.alvarez@innotechalberta.ca |