Carbon fibre is a strong, light and energy-efficient material powering innovation in aerospace, automotive and renewable energy. Approximately 90% of carbon fibre is currently produced from high-cost synthetic precursor material, polyacrylonitrile (PAN). While PAN-based carbon fibre is valued for its superior strength and performance, the high expense of the precursor material restricts broader adoption in other industries.

Alberta Innovates and InnoTech Alberta are unlocking new opportunities by developing carbon fibre from bitumen-derived feedstocks. Carbon fibre derived from bitumen offers potential advantages of lower feedstock costs and diversification of applications, creating the market for high-value, non-combustion carbon fibre products. This aligns with Alberta’s Bitumen Advanced Materials (BAM) strategies to secure long-term prosperity.

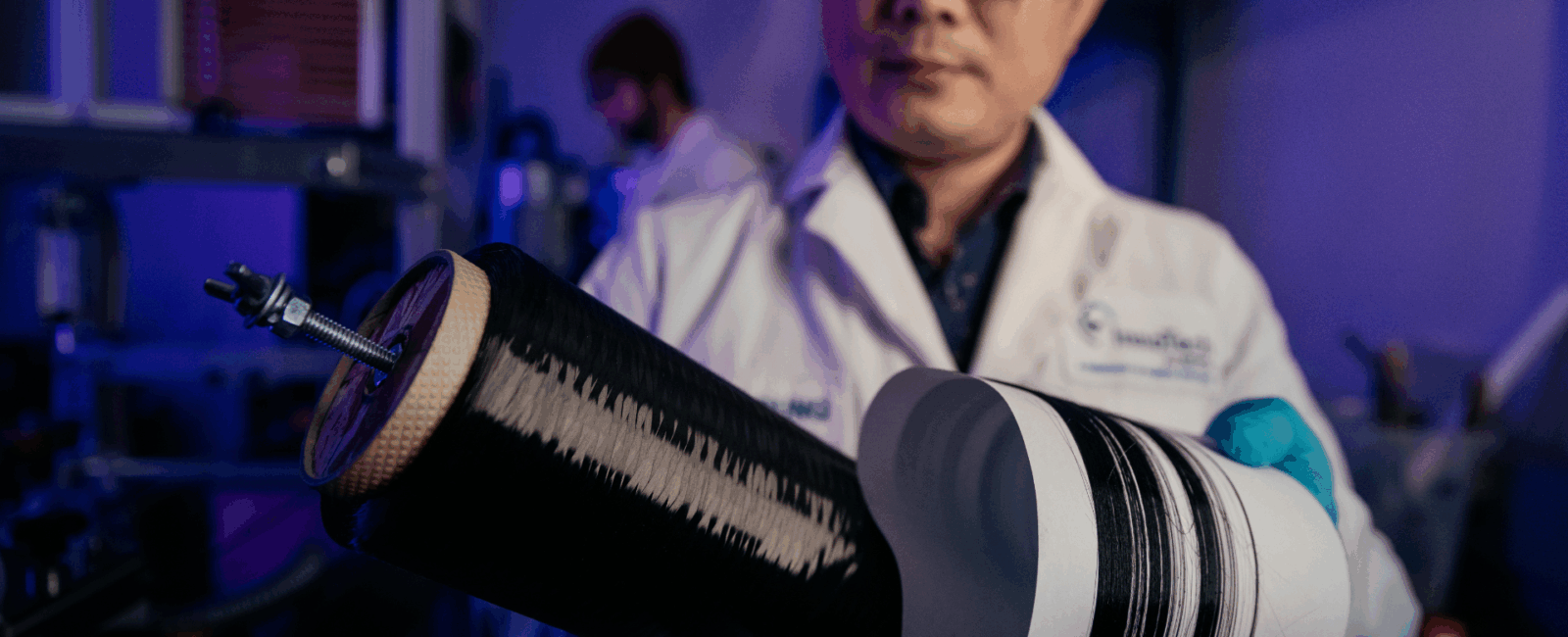

InnoTech Alberta is home to Canada’s first industry accessible, fully integrated Carbon Fibre Processing Facility, funded by Prairies Economic Development Canada.

From feedstock preparation to final fibre production, our capabilities span small-batch runs to continuous pilot-scale processing, giving innovators flexible pathways from concept to commercialization.

Our team is backed by 15+ years of expertise in hydrocarbon processing and carbon fibre development which, combined with infrastructure and know-how, has accelerated innovation in carbon fibre production from non-synthetic materials.

Our Carbon Fibre Processing Facility includes:

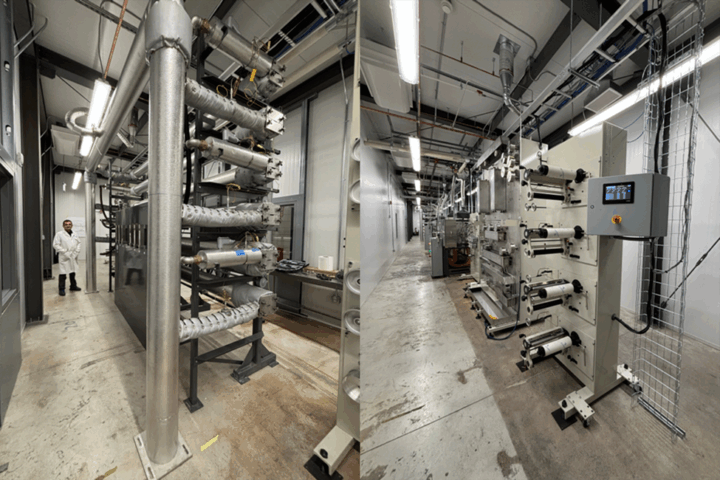

(Image: The lab-scale continuous line – unwinder (left), carbonization furnace and winder (right).)

|

|

Lab-scale |

Pilot-scale |

|

Manufacturer |

DIENES Apparatebau GmbH |

Harper International |

|

Max Material Throughput (g/h) |

25 |

125 |

|

Max Stabilization Temp. (°C) |

300 |

325 |

|

Max Carbonization Temp. (°C) |

1500 |

2400 |

|

Surface Treatment |

– |

Wash and sizing bath |

Feedstock preparation and pre-treatment includes:

Analytical support offers testing services in several areas, including mechanical, chemical and microscopy.

(Image: The pilot-scale continuous line – stabilization oven (left), surface treatment and winder (right).)

| Neil Yaremchuk Phone # 780-450-4628 Email neil.yaremchuk@innotechalberta.ca |

Jose Alvarez Phone # 780-450-5395 Email jose.alvarez@innotechalberta.ca |