InnoTech Alberta and its predecessors have played an important role in the development of hot water bitumen extraction technology and the overall growth of Alberta’s oil sands industry. Today, we continue the mandate of supporting the oil sands industry by: reducing bottlenecks and transforming existing technologies and processes; developing new technologies; and evaluating technologies, chemical products, and equipment as an impartial third party.

Our expertise and experience cover the full life cycle of the minable oil sands, including ore mining, slurry conditioning and hydro transport, bitumen liberation, froth treatment, partial upgrading, and tailings treatment.

The Denver D12 machine has been the industry standard for laboratory froth flotation testing. It could be used to study oil sands ore extractability, to determine optimal operating parameters at bench scale, to evaluate bitumen liberation processing aids, and to investigate impacts of changing bitumen separation process on the characteristics and behaviour of the produced tailings.

The Batch Extraction Unit (BEU) is used to extract bitumen froth from oil sand at bench scale The BEU is a useful aid to determine extractability based on ore quality, chemical additives and operating parameters with appropriate bitumen/water/solids analyses. InnoTech Alberta offers the sale of BEUs in addition to bench-scale batch extraction services.

The experimental set up and operation described is used to extract bitumen froth from oil sand to determine extractability based on ore quality and variable test conditions. It has been designed to simulate a slurry transport loop.

We research and advance the process of froth treatment for oil sands clients. This refers to the process of removing water and minerals (usually using naphthenic or paraffinic methods) so that the viscosity of the bitumen is reduced and can be processed.

The process involves injecting light hydrocarbon and then mixing it with the bitumen froth, it is then subjected to a froth separator to separate this mixture using gravity. The hydrocarbon can then be recycled and put through this process again until it is clean enough to be recovered (generally <1% water and <1% solids)

In oil sands tailings R&D, we work with producers, regulatory agencies, chemical manufactures, and device suppliers to provide technical solutions and services in evaluation and development of treatment technologies to enhance, accelerate, and improve the dewatering and densification of tailings and deposits to achieve the goal of reclamation ready soils.

Our tailings geotechnics lab can carry out standard and customized geotechnical engineering measurements on materials from slurry to soils and soft rocks. We are capable of testing and modelling the processes of sedimentation, large strain consolidation, and desiccation of treated or untreated tailings and deposits from lab to field scales.

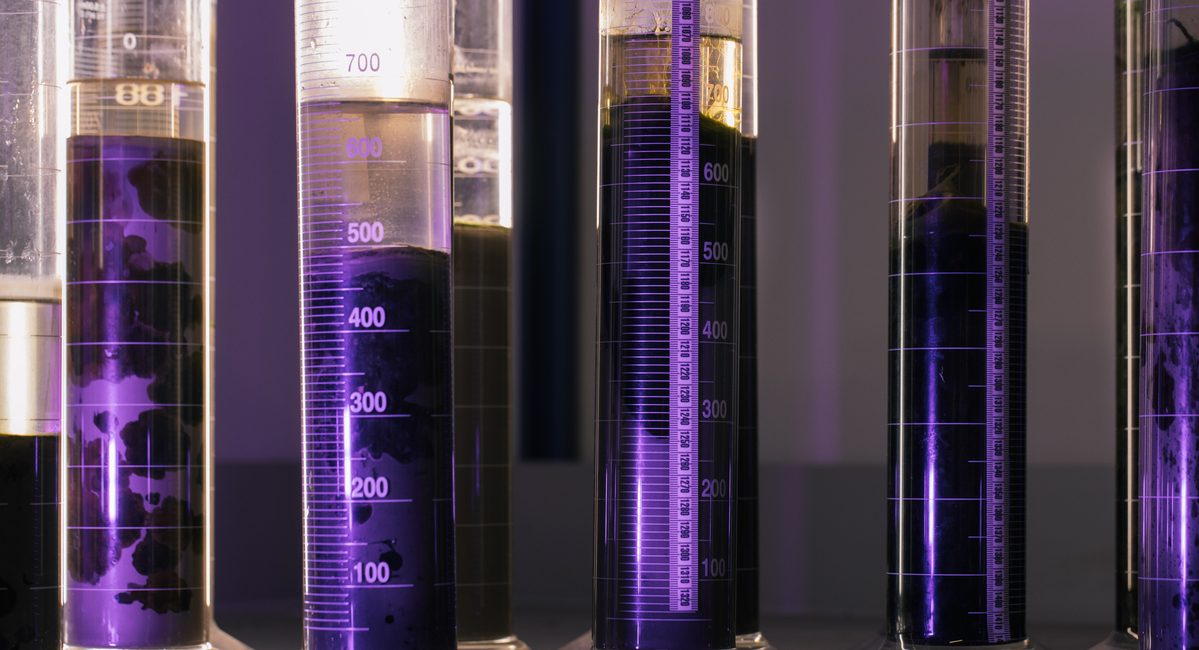

Our capacities include Lemitec MD-80 Horizontal Decanter Centrifuge for accelerated dewatering; Large Settling Columns to study the settling process of slurries; Large Strain Consolidometers for measuring the compressibility, permeability, and strength of tailings of very high initial water contents and void ratios; GEONOR Fall Cone Apparatus for measuring Liquid Limits, undrained shear strength and sensitivity of soft materials and GDS Automated Triaxial Testing System for studying the strength and deformation behaviour of both saturated and unsaturated soils; for measuring relative permeability and soil water characteristics curves.